Advantages And Disadvantages Of G10 Material

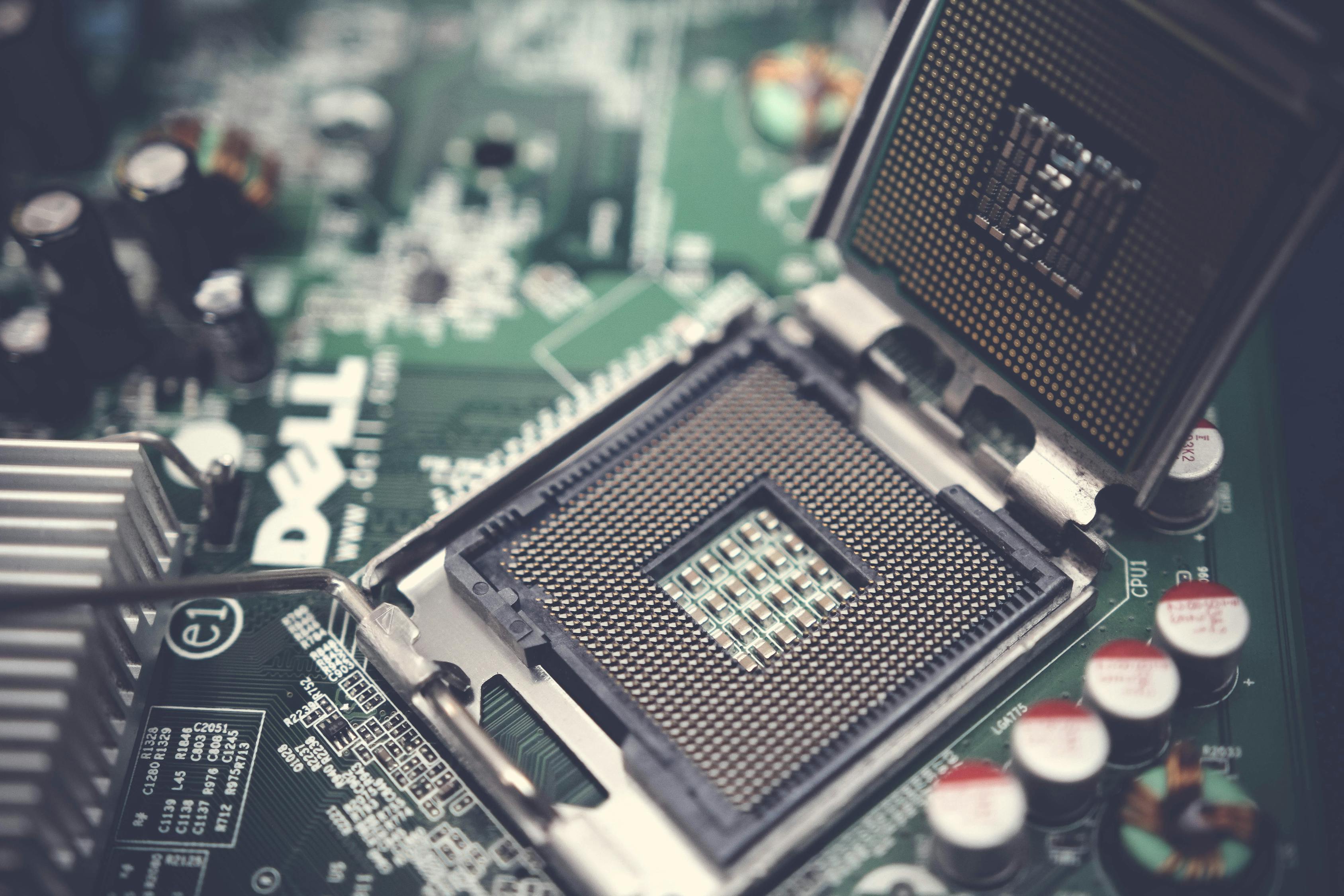

A thermosetting industrial laminate, G10 is commonly used in electrical boards and circuit boards. It is an excellent material for electrical circuits because of its durability and resistance to corrosion. It is also simple to manufacture and has low thermal expansion. However, it's not an ordinary plastic. It is made to the specifications of. A special machine is required to create an appropriate bracket or mount for an electrical motor. You should also consult an expert prior to undertaking the task.

As a strong electrical insulation that is low-temperature, G10 is perfect for circuit board applications. It is a tough, rigid, and thermally-stable material. These properties are crucial to circuit boards since they could get hot and lose their elasticity during use. If the material is used to make circuit boards it could lead to the computer to malfunction and damage itself. The material is popular for a variety of purposes.

G10's low maintenance requirements are another benefit. It is a non-combustible product that is not rusty or alter its appearance. It is also extremely sturdy and does not bend or soften over time. This makes it an excellent material for a wide range of assembly requirements for equipment. It's also a great choice for rocket motor casings and other similar applications. It is tough and resistant to chemical damage, similar to mother of pearl.

G-10's strength at high temperatures makes it ideal for electrical insulation applications. Unlike its flame-retardant cousin, FR-4, G-10's UL flammability rating is 94 V-0. It is available in both tubes and flat sheets, which are easy to handle. The flexible material can be formed into a variety of sizes, shapes, and thicknesses. You can also make bent rods or angles by using it as a heat-resistant alternative to fiberglass.

G10 is not fiberglass. It is an unidirectional material composed of epoxy resin and fiberglass. It is extremely durable and can withstand accidental drops as well as direct blows from hammers. G10's durability is an important aspect. In addition to its durability, G10 is waterproof. Natural materials, such as FR-4 and FR-10 are susceptible to changes in humidity. But G10 Material can endure fluctuations in humidity.

Due to its thermoset characteristics, G10 is the preferred option for electrical circuit boards. It is ideal as an electrical insulator due its strength. It is also an alternative to metal that is lightweight. It is also very light. Hence, it is suitable for other applications. In addition to electrical applications, G10 is also widely employed in knife handles. Therefore, it is crucial to select the right material for your project. It should be flexible, durable and be able to meet the requirements of the end-user.

G10 is thermosetting laminate composed of epoxy resin and glass fabric. The material is stable across temperatures and humidity, and has a high strength to weight ratio. Due to these characteristics it is a great material for use in the electrical industry. It can be isolated to a high efficiency when employed in a specific application. It is able to be put into many different configurations including military and commercial applications.